Vibrating Equipments- Vibro Energy Finishing Machines

STAR TRACE VIBRATORY FINISHING MACHINES ARE SUITABLE FOR DEBURRING, DESCALING, EDGE RADIUSING, POLISHING, SURFACE IMPORVEMENT, PRE PLATING FINISHING ALL TYPES OF COMPONENTS INCLUDING FULLY MACHINED PARTS IN METALS & PLASTICS

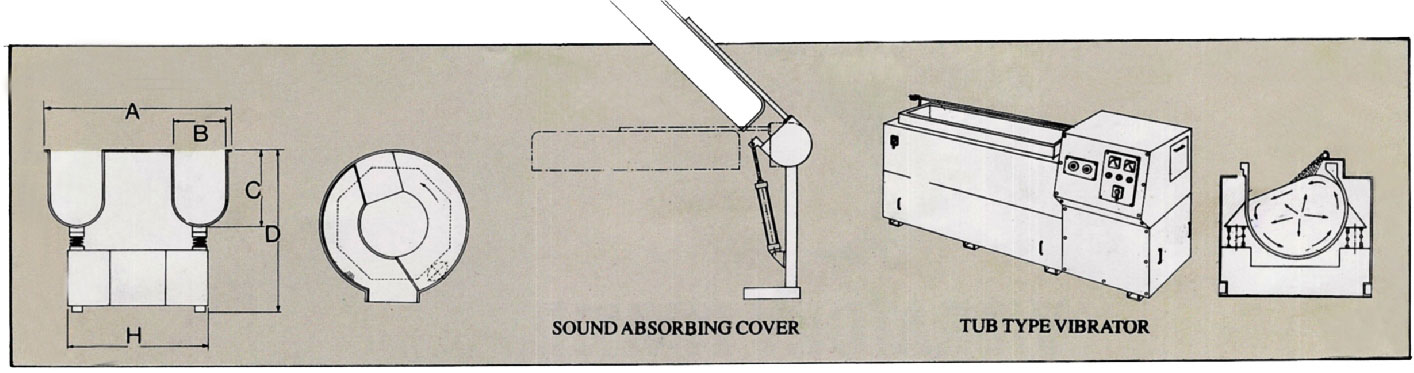

PRINCIPLE OF STAR TRACE VIBRATORY MACHINES

In the STAR TRACE vibratory finishing machines the media and the components which are carried through the tub/bowl vibrate and travel forward in a spiral or corkscrew motion with the generated vibration.

ADVANTAGES OF STAR TRACE VIBRATORY MACHINES

- Continuous treatment.

- No point of rest for components and media during process.

- Much shorter processing time than conventional barreling.

- Much gentler action.

- No risk of damage, deflection or distortion while processing delicate components.

- Components may be inspected at any time without stopping the machine.

MODEL |

CAPACITY liters |

Dia A mm |

B mm |

C mm |

D mm |

H mm |

MOTOR H.P |

ST 30 |

30 |

740 |

150 |

270 |

900 |

600 |

0.5 |

| ST 80 |

80 |

970 |

250 |

300 |

900 |

650 |

1.5 |

ST 150 |

150 |

1180 |

270 |

350 |

950 |

870 |

2.0 |

ST 200 |

200 |

1200 |

280 |

400 |

1000 |

900 |

2.5 |

ST 300 |

300 |

1350 |

300 |

450 |

1050 |

1050 |

3.5 |

ST 450 |

450 |

1550 |

400 |

500 |

1100 |

1150 |

5.5 |

ST 650 |

650 |

1650 |

460 |

550 |

1125 |

1250 |

7.5 |

ST 800 |

800 |

1950 |

500 |

700 |

1650 |

1400 |

10.0 |

ST 1050 |

1050 |

2200 |

350 |

950 |

1550 |

1600 |

12.0 |

MODEL |

CAPACITY liters |

FILLING kg |

INLET LXW(mm) |

M/C DIMENSIONS LXWH(mm) |

MOTOR H.P |

STR-50 |

50 |

100 |

510 x 220 |

1120 x 540 x 900 |

3.0 |

STR-150 |

150 |

300 |

950 x 350 |

1560 x 1150 x1240 |

7.5 |

STR-300 |

300 |

600 |

1560 x 320 |

2230 x 750 x 1260 |

15.0 |

STR-380 |

380 |

760 |

1150 x 505 |

1805 x 1430 x 1415 |

15.0 |

STR-500 |

500 |

1000 |

1630 x 380 |

2230 N 830 x 1380 |

18.0 |